Email Us

sales@rioengg.com

Call Us

+91 9136530431Email Us

Call Us

+91 9136530431

Rio Engineering stands as a leading manufacturer in the industrial flange sector, delivering precision-engineered solutions that meet the demanding requirements of modern industrial applications. With decades of experience in metallurgy and manufacturing, the company has established itself as a trusted partner for industries ranging from oil and gas to chemical processing and power generation.

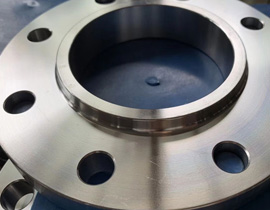

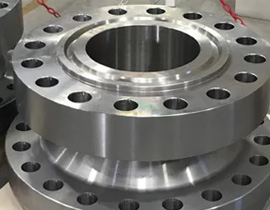

Rio Engineering specializes in producing a comprehensive range of flanges, including weld neck, slip-on, blind, socket weld, and threaded varieties. Their state-of-the-art manufacturing facility employs advanced CNC machining centers, automated welding systems, and precision forging equipment to ensure consistent quality and dimensional accuracy. The company maintains strict adherence to international standards including ASME B16.5, ASME B16.47, and API 6A specifications.

The company sources premium-grade materials including carbon steel, stainless steel, alloy steel, and exotic materials like Inconel and Hastelloy. Each flange undergoes rigorous quality control processes, including dimensional inspection, material verification, and pressure testing. Rio Engineering's ISO 9001:2015 certified quality management system ensures traceability and reliability throughout the manufacturing process.

Rio Engineering's flanges serve critical applications across multiple sectors. In the petrochemical industry, their products withstand extreme pressures and corrosive environments. Power plants rely on their high-temperature flanges for steam and gas turbine applications. The company also serves the pharmaceutical, food processing, and water treatment industries with sanitary and corrosion-resistant flange solutions.

Beyond manufacturing, Rio Engineering provides comprehensive engineering support, including custom design services and technical consultation. Their experienced team works closely with clients to develop application-specific solutions that optimize performance and reduce lifecycle costs. With a commitment to continuous improvement and customer satisfaction, Rio Engineering continues to set industry standards for flange manufacturing excellence, ensuring reliable connections in critical industrial systems worldwide.

| Specifications | : | ASTM A182 / ASME SA182 |

| Size | : | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards |

: | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17-11-02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316 | 0.08 max | 2 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 316 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

USA, China, United Arab Emirates, Saudi Arabia, Germany, United Kingdom, Netherlands, Italy, France, Belgium, Australia, Japan, South Korea, Singapore, Malaysia, Vietnam, Indonesia, Thailand, Bangladesh, Nepal, Sri Lanka, South Africa, Egypt, Kenya, Nigeria, Brazil, Mexico, Canada, Russia, Turkey.

Ahmedabad, Pune, Ludhiana, Faridabad, Surat, Jamshedpur, Coimbatore, Nashik, Vadodara, Kanpur, Rajkot, Indore, Tiruchirappalli, Aurangabad, Bhilai, Visakhapatnam, Bhiwadi, Chandigarh, Nagpur, Jaipur, Bokaro Steel City, Durgapur, Noida, Ghaziabad, Vapi, Kolhapur, Thane, Mangalore, Hyderabad, Chennai.