Email Us

sales@rioengg.com

Call Us

+91 9136530431Email Us

Call Us

+91 9136530431

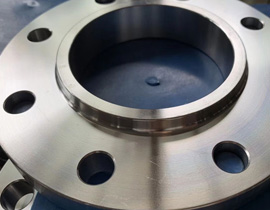

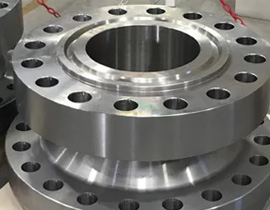

The Slip On Flanges is slipped over the pipe and is settled by welding at both the top and base sides of the flange. They are used to provide sufficient strength to the connection and prevent leakage. This flange is favored over weld neck flanges as less accuracy is required when cutting pipe to length, the cost to produce is lower but there is nearly the same outcome.

The calculated strength from Slip On flanges under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third that of the latter.

The connection with the pipe is done with 2 fillet welds, as well as at the outside also at the inside of the flange.

The X measure on the image is approximate:

Wall thickness of pipe + 3 mm.

This space is necessary, to do not damage the flange face, during the welding process.

A disadvantage of the flange is, that principle always firstly a pipe must be welded and then just a fitting. A combination of flange and elbow or flange and tee is not possible, because named fittings have not a straight end, that complete slid in the Slip On flanges.

| Item | Details |

|---|---|

| Material Grades | Stainless Steel, Duplex Steel, Super Duplex, Nickel, Monel, Inconel, Incoloy, Hastelloy |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / Threaded / Screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

USA, China, United Arab Emirates, Saudi Arabia, Germany, United Kingdom, Netherlands, Italy, France, Belgium, Australia, Japan, South Korea, Singapore, Malaysia, Vietnam, Indonesia, Thailand, Bangladesh, Nepal, Sri Lanka, South Africa, Egypt, Kenya, Nigeria, Brazil, Mexico, Canada, Russia, Turkey.

Ahmedabad, Pune, Ludhiana, Faridabad, Surat, Jamshedpur, Coimbatore, Nashik, Vadodara, Kanpur, Rajkot, Indore, Tiruchirappalli, Aurangabad, Bhilai, Visakhapatnam, Bhiwadi, Chandigarh, Nagpur, Jaipur, Bokaro Steel City, Durgapur, Noida, Ghaziabad, Vapi, Kolhapur, Thane, Mangalore, Hyderabad, Chennai.