Email Us

sales@rioengg.com

Call Us

+91 9136530431Email Us

Call Us

+91 9136530431

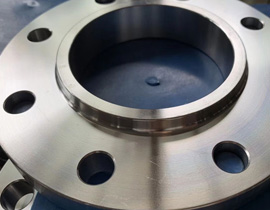

Socket Weld flanges were initially developed for use on small-size high-pressure piping. Their static strength is equal to Slip-On flanges, but their fatigue strength 50% greater than double-welded Slip-On flanges.

The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, space must be created between flange or fitting and pipe.

ASME B31.1 1998 127.3 Preparation for Welding (E) Socket Weld Flanges Assembly says: In an assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16? (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.

The purpose of the bottoming clearance in a Socket Weld Flanges is usually to reduce the residual stress at the root of the weld that could occur during the solidification of the weld metal.

The disadvantage of this flange is right the gap, that must be made. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange can give corrosion problems. In some processes, socket weld flanges are also not allowed.

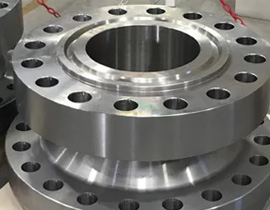

| Item | Details |

|---|---|

| Material Grades | Stainless Steel, Duplex Steel, Super Duplex, Nickel, Monel, Inconel, Incoloy, Hastelloy |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / Threaded / Screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

USA, China, United Arab Emirates, Saudi Arabia, Germany, United Kingdom, Netherlands, Italy, France, Belgium, Australia, Japan, South Korea, Singapore, Malaysia, Vietnam, Indonesia, Thailand, Bangladesh, Nepal, Sri Lanka, South Africa, Egypt, Kenya, Nigeria, Brazil, Mexico, Canada, Russia, Turkey.

Ahmedabad, Pune, Ludhiana, Faridabad, Surat, Jamshedpur, Coimbatore, Nashik, Vadodara, Kanpur, Rajkot, Indore, Tiruchirappalli, Aurangabad, Bhilai, Visakhapatnam, Bhiwadi, Chandigarh, Nagpur, Jaipur, Bokaro Steel City, Durgapur, Noida, Ghaziabad, Vapi, Kolhapur, Thane, Mangalore, Hyderabad, Chennai.