Email Us

sales@rioengg.com

Call Us

+91 9136530431Email Us

Call Us

+91 9136530431

Rio Engineering are leading manufacturers of flanges and Pipe Fittings from Mumbai, Maharashtra, India. We manufacture FORGE FITTINGS – Forged BOSS as per International standard and material Grad. These products are available in various sizes, shapes, and designs as per the specific requirements of our clients.

Rio Engineering is a manufacturer, Stockiest and Exporter of Premium quality treaded boss, stainless steel flanges, and stainless steel pipe fittings that are manufactured under the expert guidance of our diligent workforce. Our ASME B16.11 / BS3799 forged boss and other fitting products are manufactured by using quality material and a quality check process. Designed in compliance with international quality standards which are corrosion resistance, sturdy and durable.

| Grade | Stainless Steel Round Bar |

|---|---|

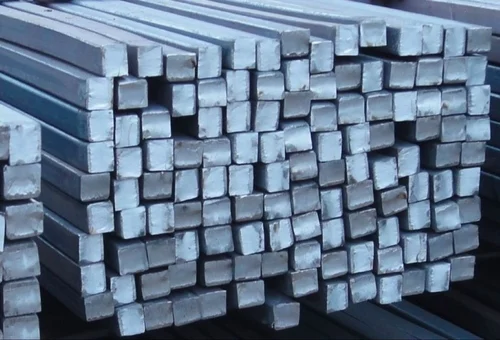

| Stainless Steel Square bar size | 4 to 100mm |

| Stainless Steel Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Hot Rolled Steel Hex Bar size | 2-100mm A/F |

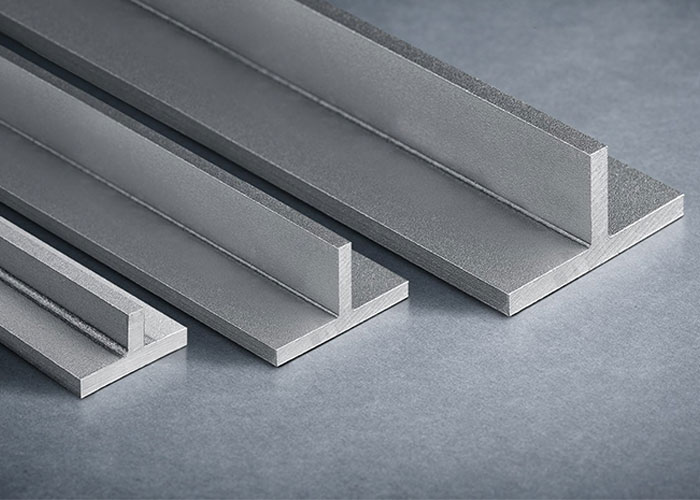

| Stainless Steel Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Stainless Steel Rectangles Size | 33 x 30mm to 295 x 1066mm |

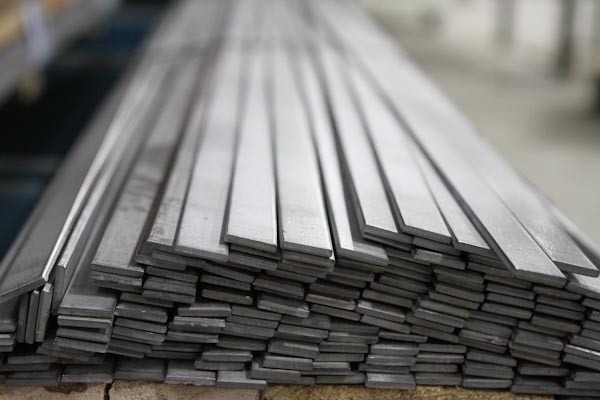

| Hot Rolled Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

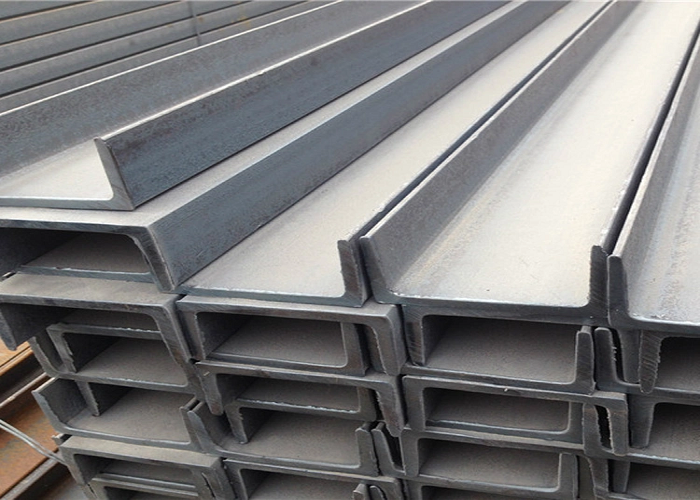

| Stainless Steel Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Stainless Steel Section | 3.0 to 12.0mm thickness |

| Hot Rolled Steel Round bar size | Diameter: 3-~800mm |

| Stainless Steel Billet Size | 1/2" to 495mm Diameter |

| Stainless Steel Round Bar Standard Dimensions | Diameter / Height: Stainless Steel Rod and Bar Sizes : 0.5 inches / 0.625 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches. |

| Stainless Steel Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Stainless Steel Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Hot Rolled Steel Technique | Stainless Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Stainless Steel Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Stainless Steel Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square Bar, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Stainless Steel | ASTM / ASME SA 276, A479 TP 202, 304, 304L, 309S, 309H, 310S, 316, 316L, 316 TI, 317, 321, 347, 410, 420, 430, 431, 440A, B & C., 446 |

| Duplex Steel | 2205 (UNS No. S31803), 2507 (UNS No. S32750) |

| Super Duplex Steel | ASTM / ASME SA A582, A276, A564, ASTM A484, 484M UNS NO. S32750 / S32760 / S32950 |

| Carbon Steel | ASTM / ASME A 105, A53 GR B, A106GR B, API5L GRADE B, API 5L, GRX42 / 46 / 52 / 56 / 60 / 65 / 70, A333 GR 1/GR 3/GR 6, A/SA 672 GR 8C60/C70 etc.. |

| Alloy Steel | ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91. ASTM / ASME A 729 GR B 11 & B 22. |

| Nickel Alloy | ASTM / ASME SB 160 Nickel 200 (N02200), Nickel 201 (N02201), Nickel 205 (N02205) |

| Monel | ASTM / ASME SB 164 Monel 400 (N04400), Monel 500 (N05500) |

| Inconel | ASTM B408, AMS 5766, ISO 9723, ISO 9724, BS 3076NA15, BS 3075NA15, EN 10095, VdTüV 412 & 434 Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750, Incoloy 800, incoloy 825, Incoloy 925, Incoloy a-286 |

| Hastelloy | Hastelloy C22, Hastelloy C276, Hastelloy C4, Hastelloy B, Hastelloy C-2000 |

| Cupro Nickel Alloy | UNS No. C70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C10100, 10200, 10300, 10800, 12000, 12200, |

|

MATERIAL

|

ASTM | EQUIVALENT STANDARD | |||

| UNS | GRADE (TP) | DIN (EN) | AFNOR (NF) | JAPAN (JIS) | |

|

AUSTENTIC STAINLESS STEEL

|

S30400 | 304 | 1.4301 | Z6CN18-09 | SUS304 |

| S30403 | 304L | 1.4307 | Z2CN18-10 | SUS304L | |

| S31600 | 316 | 1.4401 | Z6CND17-11 | SUS316 | |

| S31603 | 316L | 1.4404 | Z2CND17-12 | SUS316L | |

| S31635 | 316Ti | 1.4571 | Z2CND17-12 | - | |

| S32100 | 321 | 1.4541 | Z6CNT18-10 | SUS321 | |

| S34700 | 347 | 1.455 | Z6CNNb18-10 | SUS347 | |

| S30409 | 304H | 1.4948 | Z6CN19-10 | SUS304H | |

| S31609 | 316H | 1.4919 | Z6CND17-12 | SUS316H | |

| S32109 | 321H | 1.4941 | Z10CND18-10 | SUS321H | |

| S31000 | 310 | - | - | SUS310 | |

| S31703 | 317L | 1.4438 | - | SUS317L | |

|

FERRITIC STAINLESS STEEL

|

S40500 | 405 | 1.4002 | Z6CAL13 | SUS405 |

| S41000 | 410 | 1.4006 | Z12C13 | SUS410 | |

| S43000 | 430 | 1.4016 | Z10C17 | SUS430 | |

|

DUPLEX STAINLESS STEEL

|

S32205 | 2205 | 1.4462 | Z2CND22-06 | - |

| S31803 | - | 1.4462 | Z2CND22-05 | - | |

USA, China, United Arab Emirates, Saudi Arabia, Germany, United Kingdom, Netherlands, Italy, France, Belgium, Australia, Japan, South Korea, Singapore, Malaysia, Vietnam, Indonesia, Thailand, Bangladesh, Nepal, Sri Lanka, South Africa, Egypt, Kenya, Nigeria, Brazil, Mexico, Canada, Russia, Turkey.

Ahmedabad, Pune, Ludhiana, Faridabad, Surat, Jamshedpur, Coimbatore, Nashik, Vadodara, Kanpur, Rajkot, Indore, Tiruchirappalli, Aurangabad, Bhilai, Visakhapatnam, Bhiwadi, Chandigarh, Nagpur, Jaipur, Bokaro Steel City, Durgapur, Noida, Ghaziabad, Vapi, Kolhapur, Thane, Mangalore, Hyderabad, Chennai.